To: Multi-Tech Products

I am a spa surface repair contractor, and I perform manufacturer warranty work and non-warranty repairs. I have a customer with an acrylic spa containing a crack at the rim. What causes these type of problems, and what is correct method to repair?

Thanks,

Carlos

To: Carlos

Carlos, thanks for your inquiry. The information I am about to share will be very valuable to you, and other repair technicians. It will enhance your overall knowledge on troubleshooting spa problems, and improve your repair results. It will minimize the potential of returning at a later date to fix the same or additional cracks. This will make you a more valuable resource to your manufacturer clients for warranty repairs. We also recommend that you know your manufacturers well. That includes the basics of their designs, and the terms of their warranty. Understand the manufacturer’s guidelines for installation.

If it is possible, make a visit to the manufacturer’s plant. During a complete tour, pay attention to what they use for shell support, and where it is placed. Ask about the use of insulating and structural polyurethane foam. Check the thickness of the shell in various locations. Observe if there are any unique materials or devices used to add reinforcement. One manufacturer uses large diameter PVC pipe to provide support under the key portions of the spa (picture below). Understand that a spa is a reinforced composite structure, and the details of the reinforcement are extremely important Some manufacturers even have specifications on how much deformation along the rim is allowable under normal loads.

Also, know what the shell material is. Is it monolithic acrylic, or is it co-extruded acrylic over ABS? Is it reinforced with FRP (polyester resin with chopped glass fibers), or is it polyurethane? Is a vinyl ester used in the reinforcement composite?

Your question is a very complex one. First, you did not mention whether it is a portable spa, or if it is an in-ground or in-deck installation. You also did not mention whether it is under warranty. Also, if it is a portable spa, does it have an ABS plastic pan for a bottom?

Before repairing a cracked spa, a repair professional should investigate the circumstances enough to try to determine the root cause of the crack. This may not be easy, but you should strive to define the most logical cause. First, cracks occur when the material is subjected to a stress that exceeds its strength. The material strength will decline as temperature is increased. Certain types of chemicals will also accelerate crack formation. See other blog entries that discuss chemical attack. Acrylic is known as a fairly brittle polymer, and will crack under excessive stress. Obviously, a large impact from another object will cause a crack.

In the absence of an impact, most spa cracks occur due to inadequate structural reinforcement. An 8-ft. spa may contain 400 gallons of water, which results in about 3200 pounds of weight. Add a few people, and the total weight can exceed 4000 pounds. Unless the stress ( pounds per sq. ft.) from this weight is spread over the entire surface area, it can cause a crack(s) at the high-stress points. This is typically at the rim.

So, manufacturers of portable spas must incorporate enough support beams or other devices under the rim, seats, and floor to accomplish this stress reduction. Sometimes, manufacturers fail to accomplish it 100% of the time. The following picture shows one example where the weight actually caused the vertical support boards to bow under the weight. This magnitude of deflection is very likely to cause sagging and cracking of the rim.

If you look behind the skirt of a portable spa, and see any evidence of deflection, you can conclude that additional support might be needed. Sometimes, you can determine this by checking how straight and level the top edge is. Portable spas should be placed on a concrete or other strong pad to facilitate the function of the supporting structure. If the spa has a strong ABS base, it enhances the overall performance, providing it has the required design.

In troubleshooting root causes, it is helpful to know that if the crack is separated, the area was in tension. If it is pushed together with a ridge, it was in compression.

Now, if the spa is in-ground or installed into a wooden deck, it falls to the installer to assure that ample support is included under the frame, rim, seats, and foot-well of the shell to distribute the weight around those load-bearing surface areas. A commonly used technique is to wash sand into the cavity between the shell and the excavated dirt. It is important to provide support that limits deflection in all critical areas similar to the photo above showing the use of PVC pipe. The rim area also needs to be supported. The information above will apply to analyzing the cause of cracks in these type installations.

I have included some pictures showing some examples of cracks from over stress.

The cracks can be repaired by following Multi-Tech Products’ standard crack repair procedures as shown at the following link.

http://www.multitechproducts.com/content/Procedures/SPA-REPAIR-Quick-Glaze%20_revised-10252011.pdf

The spa shown in the next photo developed cracks at the rim.

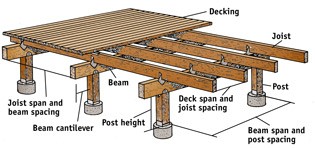

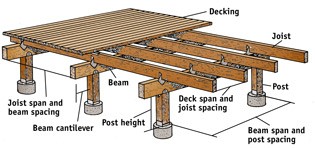

Please note the brick blocks it sits on. Unless the spa has an ABS pan base or other type of rigid platform between the bricks and the spa bottom and constructed as a self-supporting unit, it would not comply with normal installation specifications from a manufacturer Therefore, cracks would not be covered by a warranty. Most portable spas are designed to set on a strong, steel reinforced concrete pad or a wood deck with correct spacing of deck joists, correct beam span, and proportionate post pillar spacing for strong deck construction. A weak or improperly supported deck would cause the same type of crack shown in these pictures. This spa’s crack was at the center of one rim edge. This suggests the spa is suspended at the rim with little support in the critical areas mentioned above. Large spas (> 7ft.) are more likely to crack in this manner. The following diagram shows one example of a well-designed deck.

A technician should inform the customer of these issues, and make a recommendation to correct the support issues. If the customer chooses to ignore the advice but still wants the contractor to perform the repair, a warranty should not be provided. Also, this example of a crack edge would require structure repair at the back of the shell before the cosmetic repair was performed. Otherwise, new cracks would likely form in the future. The best service is to fix all of the problem sources to prevent future call-backs, and an unhappy customer.

Thanks,

Ken Wolfe

Consulting Chemical Engineer